Customization Details of Rabbit Genetically Engineered Antibodies

Rabbit genetically engineered antibody customization is a tailored service that leverages modern molecular biology techniques and the unique advantages of the rabbit immune system to provide high-specificity and high-affinity antibody products for scientific research, diagnostics, drug development, and other fields. Its core lies in breaking through the limitations of traditional antibody preparation via gene cloning, engineering modification, and in vitro expression technologies, thereby achieving precise optimization and stable mass production of antibody performance. Below is a comprehensive analysis of customization details from seven dimensions: core advantages, technical platforms, service processes, customization content, key parameters, application fields, and cooperation models.

I. Core Advantages of Customization

Compared with murine antibodies, traditional hybridoma antibodies, and antibodies from other species, rabbit genetically engineered antibodies exhibit distinct performance advantages, making them the preferred solution for high-difficulty antibody preparation:

1 Ultra-high AffinityThe rabbit immune system can generate antibodies with extremely strong affinity, with an average affinity 100–1000 times that of murine antibodies. Some can even reach the nanomolar or sub-nanomolar level, enabling efficient recognition of low-abundance target antigens.

2 Broad-spectrum Antigen Recognition CapabilityRabbits possess a larger B-cell repertoire, allowing them to recognize a more diverse range of antigen epitopes. They have unique advantages in recognizing small molecules (hormones, antibiotics, pesticide residues, etc.), carbohydrates, protein post-translational modification (PTM) sites, conformation-dependent antigens, and antigens with no immunogenicity in mice.

3 Exceptional SpecificityThese antibodies can precisely distinguish subtle epitope differences (e.g., mutations, conformational changes), significantly reducing non-specific binding risks, minimizing detection errors, and improving the accuracy of experiments and applications.

4 Excellent Batch-to-batch StabilityBased on genetic engineering technology, the antibody gene sequence is clearly defined, enabling mass production through controlled in vitro expression systems. This avoids issues such as hybridoma cell line drift and gene loss, resulting in minimal batch-to-batch variation.

5 Easy Engineering ModificationDirect access to antibody gene sequences facilitates convenient modifications such as humanization, affinity maturation, fragmentation (Fab, scFv, etc.), and fluorescent labeling, making the antibodies suitable for diverse application scenarios.

6 Strong Storage and Application StabilityRabbit IgG has a unique structure, with additional disulfide bonds in the heavy chain variable region and fewer amino acids in the N-terminus and D-E loops. It is more resistant to extreme environments, making it ideal for long-term storage and various experimental conditions.

II. Core Technical Platforms

Mainstream customization services rely on mature technical systems, with the next-generation single B-cell screening technology as the core, supplemented by multi-platform collaboration to ensure antibody quality.

1 Single B-cell Screening Technology Platform (Core)This technology overcomes the limitations of low fusion efficiency in traditional hybridoma cell technology and heavy-light chain mismatching in phage display technology. The workflow is as follows: isolate antigen-specific B cells from the peripheral blood or spleen of immunized rabbits → sort single B cells via flow cytometry (a dual-fluorescence labeling strategy reduces false positives) → amplify VH/VL gene sequences by single-cell RT-PCR → construct expression vectors → obtain naturally paired high-activity antibodies via in vitro expression. This technology eliminates the need for cell fusion, has a screening cycle of only 3 weeks, can capture rare high-activity clones, maintains natural heavy-light chain pairing, and boasts a success rate far exceeding traditional technologies.

2 Supporting Platforms

Antigen Design and Preparation PlatformCovers the entire workflow of DNA synthesis, plasmid construction, protein expression, purification and modification, peptide synthesis and conjugation, and small-molecule structural analysis, ensuring immunogen quality (purity ≥ 85%).

Antibody Engineering Modification PlatformProvides customized modification services including humanization, affinity maturation, Fc fragment modification, and antibody fragmentation, meeting the requirements of therapeutic or diagnostic-grade antibodies.

High-efficiency Expression and Purification PlatformAdopts CHO, 293F mammalian cell, or cell-free expression systems, combined with purification technologies such as Protein A/G affinity chromatography, to ensure antibody purity > 90%.

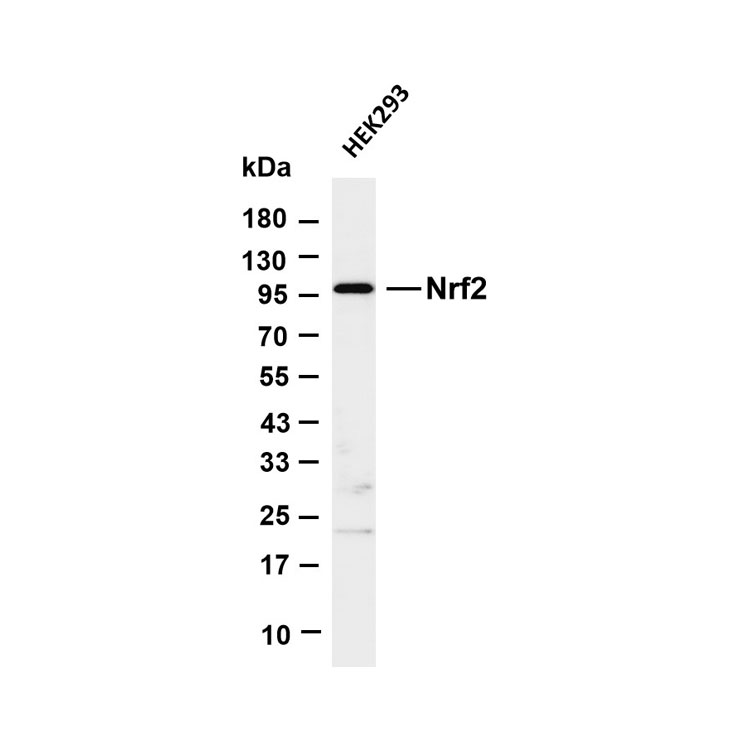

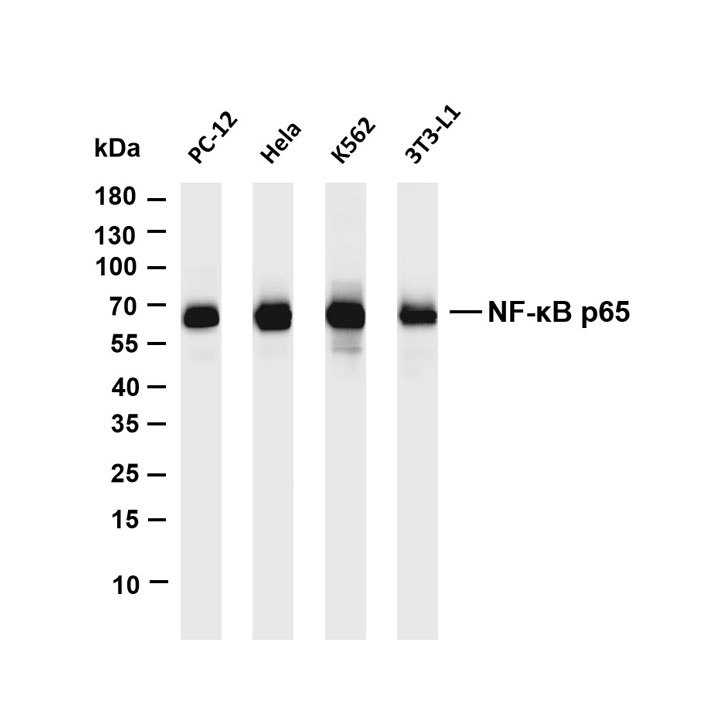

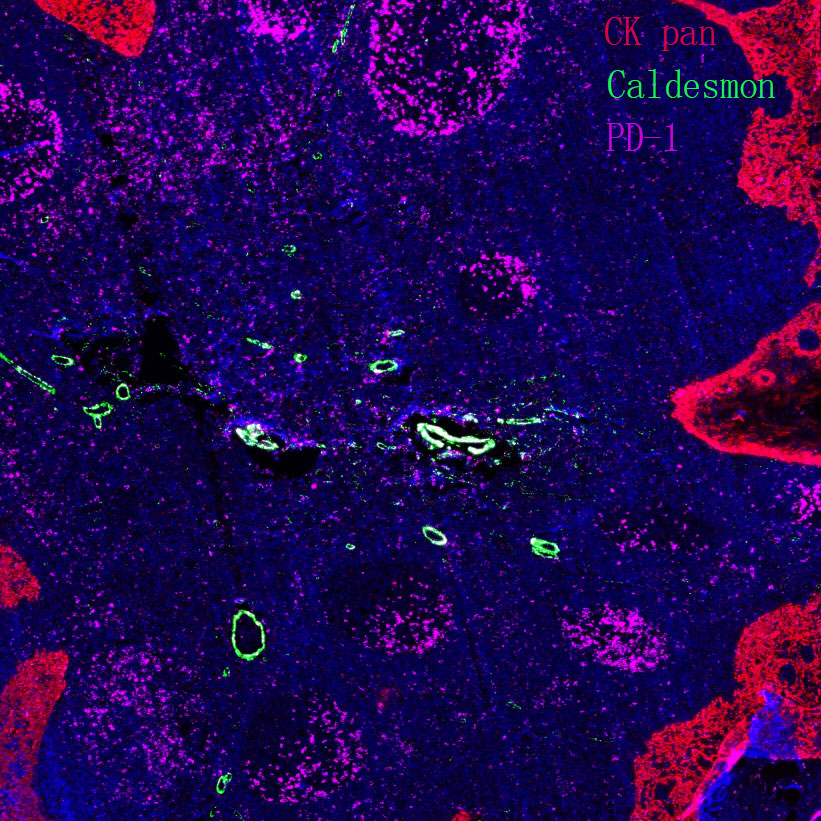

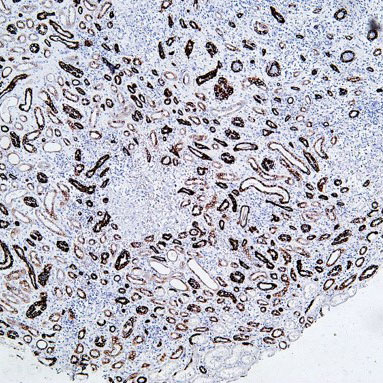

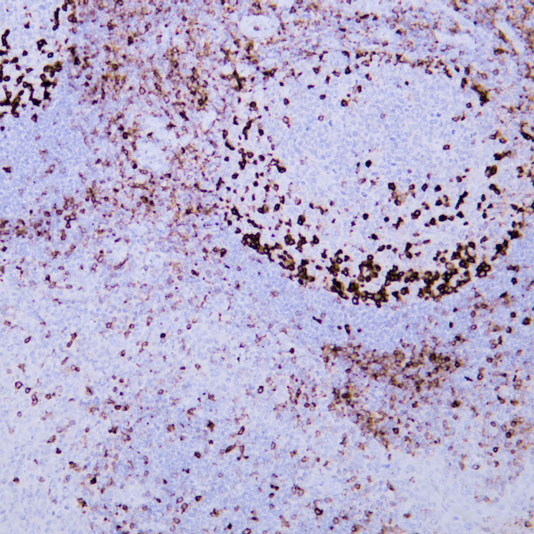

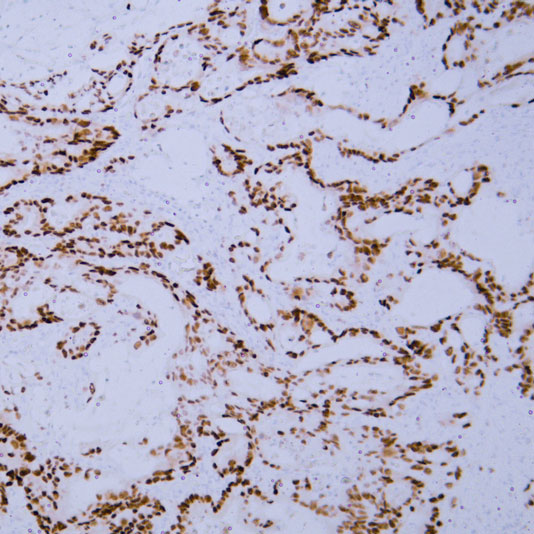

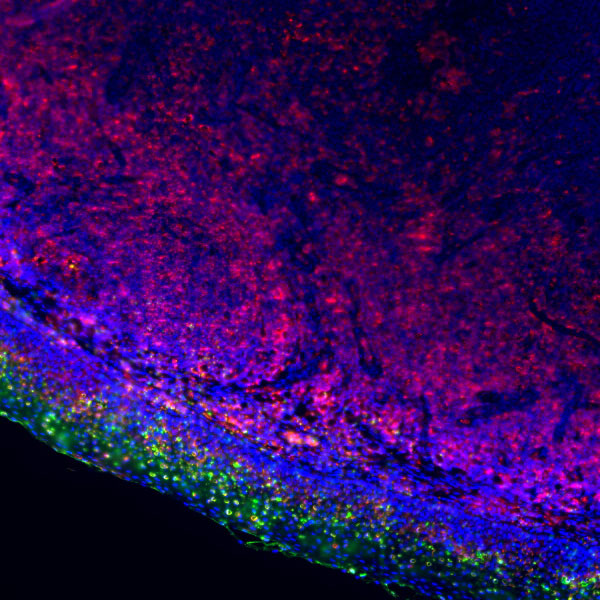

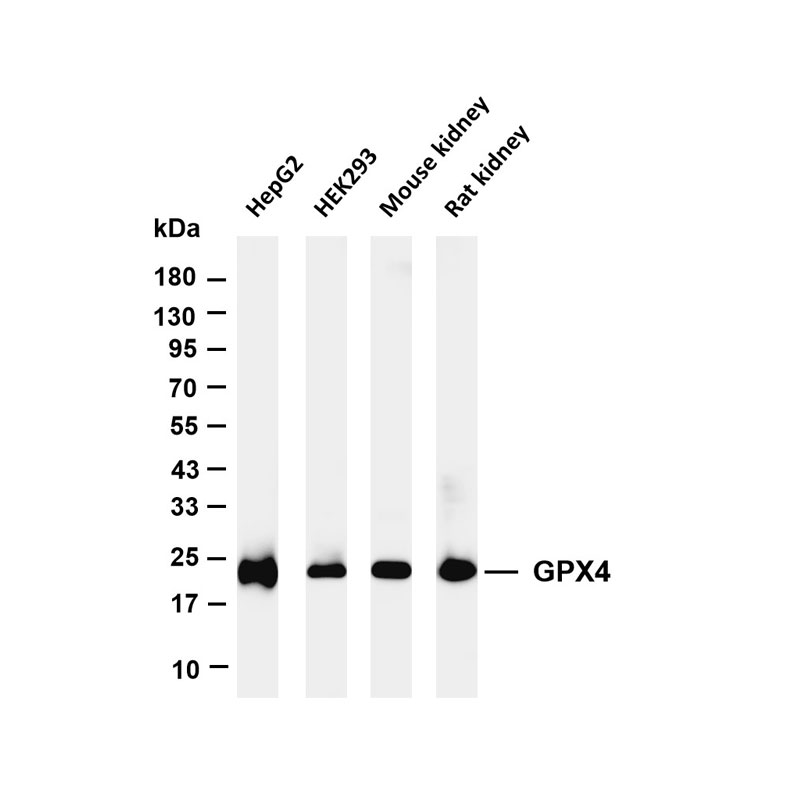

Multi-dimensional Detection and Validation PlatformComprehensively verifies antibody affinity, specificity, functional activity, and stability using techniques such as ELISA, WB (Western Blot), IHC (Immunohistochemistry), FCM (Flow Cytometry), and SPR (Surface Plasmon Resonance).

III. Detailed Customization Service Process

The customization service adopts a one-stop, fully controllable process with a standard cycle of 24–32 weeks (expedited service is available upon request, with positive clones deliverable in as little as 7 weeks). It is divided into five core phases:

Phase 1: Demand Communication and Scheme Design (1–2 weeks)Clients provide requirements: specify antigen type (protein, peptide, small molecule, DNA/RNA, etc.), application scenario (WB/IHC/ELISA/therapeutic development, etc.), antibody performance requirements (affinity, specificity, yield), delivery standards, and time nodes. The service provider evaluates feasibility, formulates a personalized scheme, clarifies antigen preparation requirements, immunization strategies, screening methods, and validation indicators, and signs a cooperation contract.

Phase 2: Antigen Design and Preparation (4–6 weeks)Antigen preparation is carried out based on antigen type: clients can provide qualified antigens themselves (≥ 8 mg for rabbit antibodies, purity ≥ 85%, homology ≤ 90%) or entrust the service provider with synthesis/preparation. The service provider conducts quality testing (purity, activity) on the antigen and retains a portion for subsequent screening and validation.

Phase 3: Animal Immunization (8–10 weeks)Healthy rabbit strains such as New Zealand white rabbits are selected, and a fractional immunization strategy combined with adjuvants is used to enhance the immune response. Serum samples are collected regularly to detect antibody titer (ELISA titer must be > 1:64,000). The next phase is initiated once the titer meets the standard.

Phase 4: B-cell Screening and Antibody Gene Cloning (4–6 weeks)Collect peripheral blood or spleen cells from immunized rabbits → isolate mononuclear cells → enrich B cells using immunomagnetic beads → sort antigen-specific IgG+ B cells via flow cytometry → sort single cells into multi-well plates → amplify VH/VL genes via RT-PCR → construct cloning vectors and perform sequencing to obtain positive clone plasmids (5–20 positive clones are routinely provided).

Phase 5: Antibody Expression, Purification, Validation, and Delivery (8–10 weeks)Select high-activity positive clones → construct expression vectors and transfect into suitable expression systems (CHO/293F, etc.) for recombinant expression → purify antibodies using technologies such as Protein A/G chromatography (purity > 90%) → conduct multi-dimensional validation: affinity detection (SPR/BLI), specificity validation (WB/IHC/FCM), stability testing (storage conditions, temperature resistance) → issue a Certificate of Analysis (CoA) and complete final delivery.

IV. Customization Service Content and Delivery Standards

Service content includes standard and customized options, with flexible combinations of deliverables based on client needs.

1 Standard Customization Service Content

Basic PackageAntigen preparation (outsourced) + rabbit immunization + positive clone screening + 1–3 positive clone plasmids and sequencing reports + 1–3 mg purified antibodies (purity > 90%) + Certificate of Analysis (CoA) + immunization report.

Advanced PackageBased on the basic package, additional services include antibody functional validation (e.g., neutralization assays, signaling pathway blocking assays), large-scale expression (gram/kg scale), and antibody labeling (fluorescein, biotin, etc.).

2 Customized Service Content

Antibody Engineering ModificationHumanization (suitable for clinical applications), affinity maturation (improving affinity to the sub-nanomolar level), Fc fragment modification (enhancing ADCC/CDC effects), antibody fragmentation (preparing Fab, scFv, bispecific antibodies, etc.).

Special Antigen CustomizationPreparation of high-difficulty antibodies such as small-molecule antibodies (hormones, pesticides, drug metabolites), PTM-modified antibodies (phosphorylation, methylation, acetylation), anti-idiotypic antibodies, and carbohydrate antigen antibodies.

Customized ValidationDesign of exclusive validation protocols based on client requirements, such as clinical sample testing, cross-reactivity testing, and long-term stability monitoring.

3 List of Core Deliverables

Antibody-related ProductsPurified antibodies (lyophilized powder/liquid, with storage buffer), positive clone cell lines/plasmids.

Technical DocumentsAntibody gene sequencing report, antigen preparation report, immunization report, purification report, Certificate of Analysis (CoA, including data on purity, concentration, affinity, specificity, etc.), and experimental methodology manual.

Remaining MaterialsLeftover antigens (> 1 mg, for outsourced synthesis scenarios) and post-immunization animal serum.

V. Key Technical Parameters and Price & Cycle

Core Technical Parameters

Antibody purity: ≥ 90% (detected by SDS-PAGE).

Antibody concentration: ≥ 1 mg/mL (detected by BCA/Bradford method).

Affinity: routinely nanomolar level, can be optimized to sub-nanomolar level (detected by SPR/BLI).

ELISA titer: supernatant titer of positive clones > 1:64,000.

Specificity: no significant cross-reactivity (validated against proteins with > 90% homology).

Storage stability: retains activity for over 12 months at -20°C/-80°C; stable for short-term storage at 4°C.

Price and Cycle ReferencePrices vary significantly based on customization difficulty, delivery standards, and yield requirements, and are subject to specific negotiation. Cycles can be adjusted according to process simplification: standard process takes 24–32 weeks; expedited process (with simplified validation steps) takes 14–26 weeks; delivery of positive clones only takes as little as 7 weeks.

VI. Core Application Fields

Thanks to their excellent performance, rabbit genetically engineered antibodies are widely used in multiple fields:

Basic Scientific ResearchProtein localization (IHC), protein detection (WB), antigen quantification (ELISA), cell analysis (FCM), protein-protein interaction studies, etc.

Clinical DiagnosticsDevelopment of high-sensitivity diagnostic kits (e.g., tumor marker detection, pathogen detection) and pathological section diagnostic probes.

Drug DevelopmentTherapeutic antibody development (anti-tumor, autoimmune diseases), drug target validation, drug metabolism detection, and neutralizing antibody screening.

Food Safety and Environmental MonitoringDevelopment of antibodies for detecting small-molecule contaminants (pesticide residues, antibiotics).

VII. Cooperation Process and Notes

Cooperation ProcessDemand consultation → Scheme evaluation and quotation → Signing contract and paying advance payment → Client providing relevant materials (antigen/demand specifications) → Experiment implementation (progress reports available throughout the process) → Mid-term communication (confirmation of screening results) → Completion of experiments and delivery of products → Payment of balance → After-sales technical support (antibody usage guidance, troubleshooting).

Notes

Antigen QualityWhen clients provide antigens themselves, they must ensure purity ≥ 85% and sufficient quantity (≥ 8 mg for rabbit antibodies), and provide relevant antigen information (sequence, structure, modification sites, etc.) to avoid affecting immunization efficacy.

Clear RequirementsClarify application scenarios and performance requirements in advance (e.g., whether humanization is needed, affinity threshold, delivery yield) to facilitate the formulation of precise schemes.

After-sales GuaranteeSelect service providers offering comprehensive after-sales support to ensure timely technical assistance for issues arising during antibody use (e.g., abnormal activity, non-specific binding).

Related Promotional Journal Downloads

30,000+ high- quality products available online

Primary Antibodies, Secondary Antibodies, mIHC Kits, ELISA Kits, Proteins, Molecular Biology Products,Cell Lines,Reagents ...

Contact Us